Showcasing Expertise and Equipment Strength

As part of our ongoing commitment to excellence, every product undergoes a rigorous inspection and testing process to ensure reliability and stability. Our Starter and Alternator series products are subjected to stringent quality control and comprehensive performance testing throughout the development and production stages. Below, we highlight the advanced equipment and rigorous testing protocols we employ, showcasing our industry expertise and equipment capabilities.

Elecdura Auto Parts Workshop[P1]

Equipment Capabilities

Each component of our Starter and Alternator products is strictly inspected to ensure high standards of quality. New series products undergo various tests before mass production, including performance testing, electromagnetic vibration, environmental testing, and endurance testing to ensure optimal performance under all working conditions.

Alternator DV Performance Tester[P2]

This device performs comprehensive performance testing on alternators, ensuring their electrical characteristics meet standards.

Electromagnetic Vibration Tester (On Working Condition)[P3]

This tester simulates working conditions to perform electromagnetic vibration tests, ensuring the products can withstand various vibrations and electromagnetic interference in actual usage.

Environment Test Area (On Working Condition)[P4]

In this testing area, we simulate various temperature and humidity conditions to thoroughly test the product’s performance in different environmental scenarios.

Starter Endurance Test Zone[P5]

Through endurance testing, we ensure that each starter motor maintains efficient and stable performance during prolonged operation.

Workshop & Management Highlights

Our product development and manufacturing processes not only draw from the essence of OE (Original Equipment) management but also blaze new paths in aftermarket management. With advanced manufacturing techniques and intelligent management, we strive for lean production in every aspect.

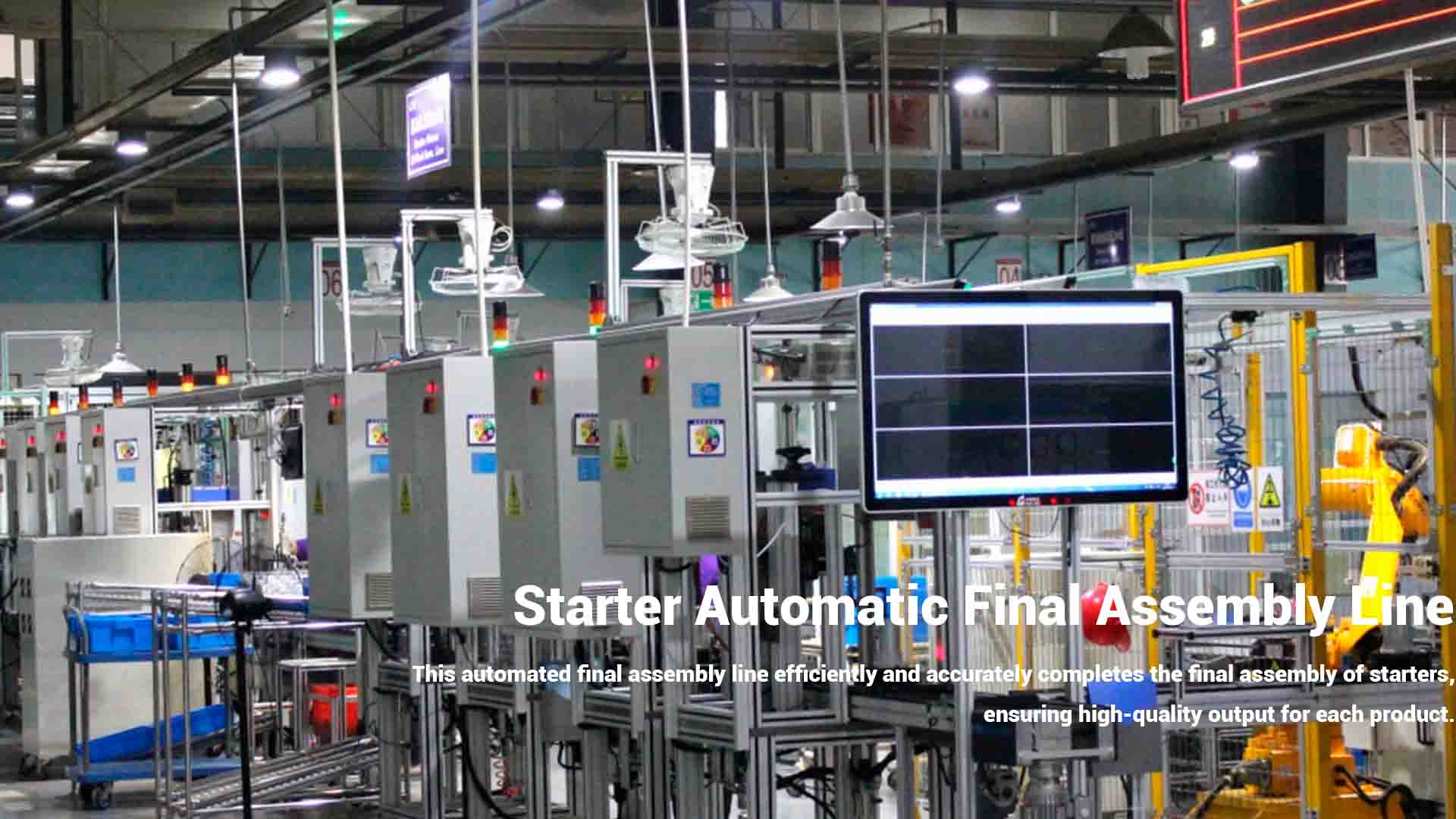

Starter Automatic Final Assembly Line[P6]

This automated final assembly line efficiently and accurately completes the final assembly of starters, ensuring high-quality output for each product.

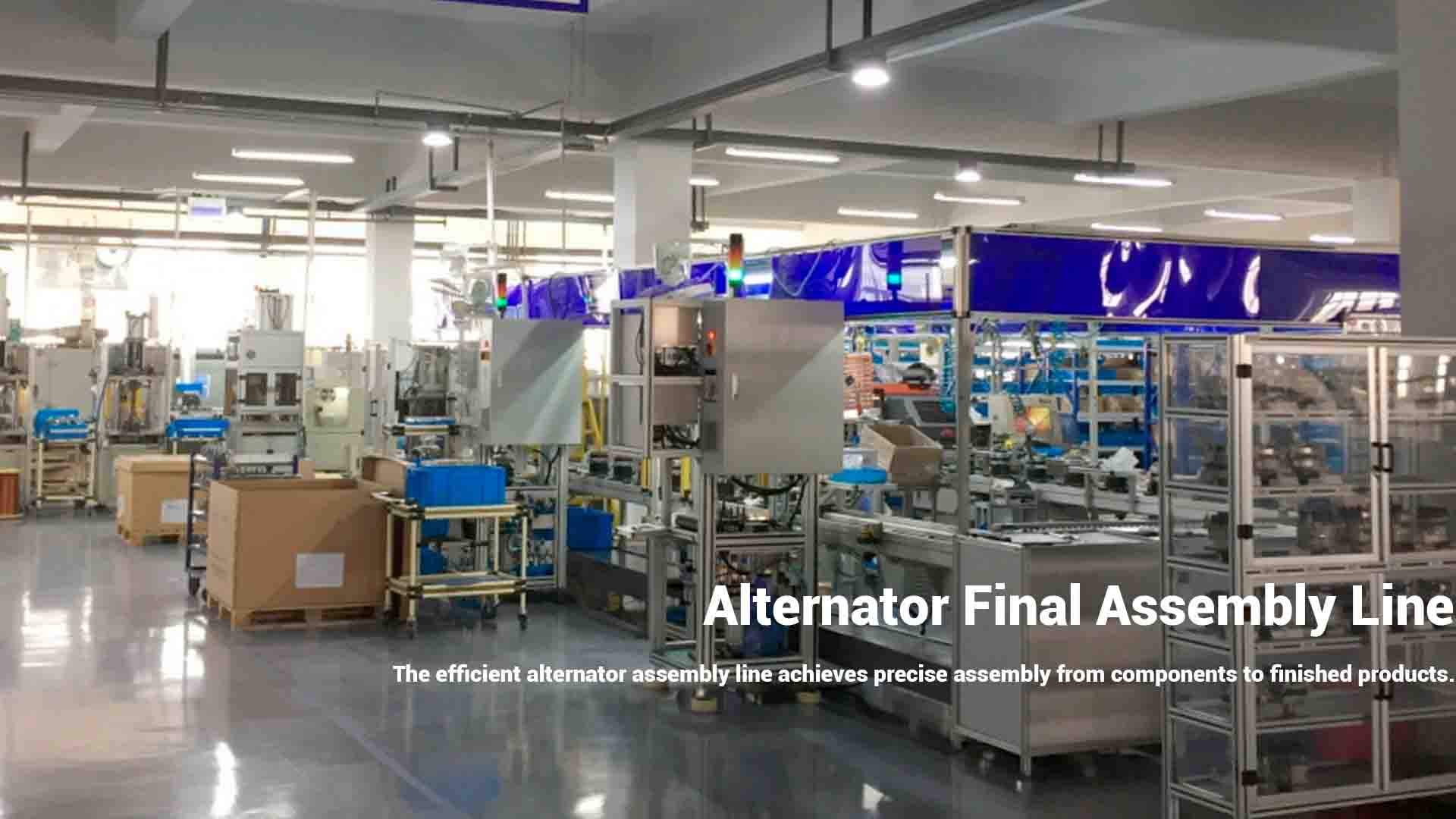

Alternator Final Assembly Line[P7]

The efficient alternator assembly line achieves precise assembly from components to finished products.

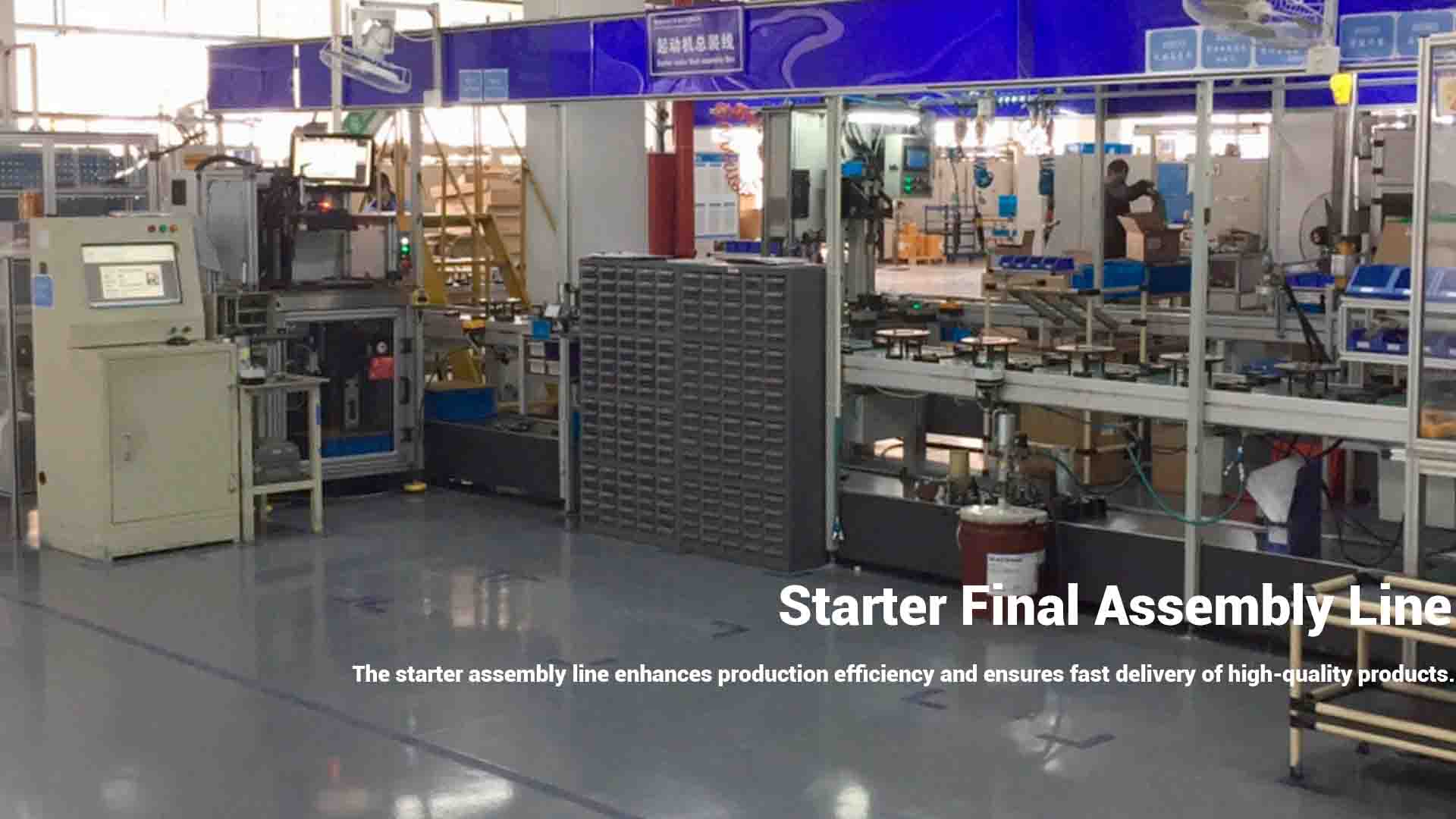

Starter Final Assembly Line[P8]

The starter assembly line enhances production efficiency and ensures fast delivery of high-quality products.

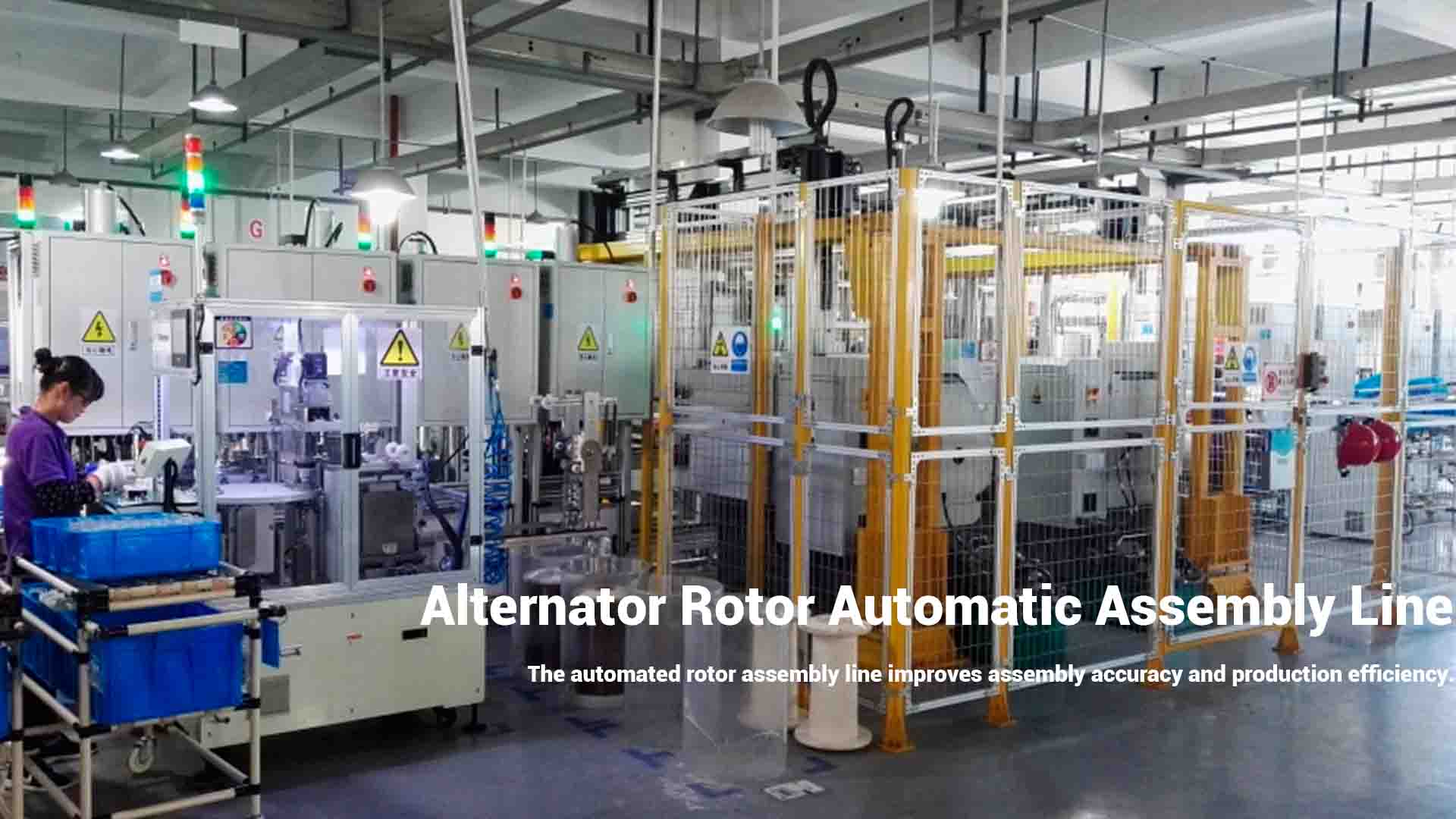

Alternator Rotor Automatic Assembly Line[P9]

The automated rotor assembly line improves assembly accuracy and production efficiency.

With our advanced technology, comprehensive testing, and efficient production processes, we not only guarantee high-quality Starter and Alternator products but also excel in handling large-scale wholesale orders. Our seamless production lines, precise quality control, and capacity for mass production ensure that we can meet the demands of our B2B clients with speed and consistency. Whether it’s for bulk supply or OEM orders, we are your trusted partner for reliable, high-performance automotive components, capable of delivering on time, every time.

Email: info@elecdura.com